A588 Corten Steel is a high-strength, low-alloy structural steel renowned for its exceptional resistance to atmospheric corrosion.

Unlike traditional carbon steel, A588 Corten Steel forms a protective oxide layer, or "patina," that significantly slows down further rusting and extends the material's lifespan-especially in outdoor and exposed environments.

This self-protecting quality is the result of its precisely balanced alloy composition, particularly the presence of copper (Cu), chromium (Cr), and nickel (Ni).

Key Alloying Elements in A588 Corten Steel

Copper (Cu):

Copper (Cu):

One of the most important elements in A588 Corten Steel, copper plays a crucial role in the formation of the weathering patina.

With copper content generally ranging from 0.25% to 0.40%, this element helps initiate and stabilize the oxide layer that adheres tightly to the steel surface.

It reduces the steel's reaction rate with moisture and oxygen, significantly slowing further corrosion.

Chromium (Cr):

Chromium enhances the adhesion and density of the protective rust layer. When A588 Corten Steel is exposed to moisture and air, chromium facilitates the formation of a more compact and adherent oxide structure.

This prevents moisture from penetrating through the rust layer and reaching the underlying metal.

Nickel (Ni):

Nickel contributes to both corrosion resistance and mechanical strength.

In A588 Corten Steel, nickel improves toughness, particularly in cold environments, and strengthens the stability of the rust layer.

It ensures the protective film is less prone to cracking or peeling off over time.

Phosphorus (P) and Silicon (Si):

Though present in smaller quantities, these elements improve the overall strength and assist in surface oxide layer stabilization.

However, phosphorus is kept below a certain limit to maintain weldability and ductility.

How A588 Corten Steel Forms a Protective Patina

When A588 Corten Steel is used in an environment with alternating wet and dry cycles-such as bridges, architectural panels, or utility structures-it begins to form a surface oxide layer.

This layer initially appears as ordinary rust but transforms into a dense, tightly bonded patina through the action of Cu, Cr, and Ni.

Over time, the patina prevents further exposure of the steel surface to corrosive elements, effectively "sealing" the metal underneath.

The formation rate and appearance of the patina can vary based on climate and environmental exposure.

In ideal conditions, a stable layer typically develops within 6 to 12 months.

Conclusion

The superior atmospheric corrosion resistance of A588 Corten Steel comes from its smart use of alloying elements like copper, chromium, and nickel.

These elements work synergistically to form a long-lasting, protective rust layer that makes A588 Corten Steel a popular choice for structures requiring durability, minimal maintenance, and a natural weathered appearance.

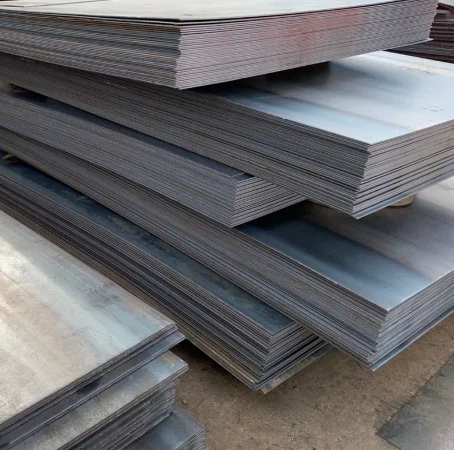

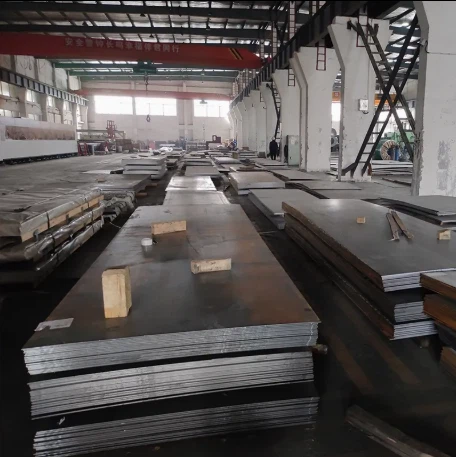

Whether in coil or plate form, A588 Corten Steel remains a trusted material in infrastructure, transportation, and architecture.